Swan Reach – Stockwell pipeline valve train replacement

The Swan Reach to Paskeville Pipeline (SRPPL) system supplies bulk water to more than 35,000 customers across the Barossa and Yorke Peninsula. The system, which is about 50 years old, performs with minimal interruption and capacity to meet peak loads plus cater for increased future demand.

Three high lift filtered water pump stations push drinking water 402 metres uphill to the Moculta Tanks. Pump Station 1 then provides a lift of 156 metres to Black and White Hills Tanks, Pump Station 2 provides a lift of 125 metres to Towitta Tanks and Pump Station 3 provides a lift of 121 metres to Moculta Tanks.

Each pump station houses three to four pumps with a maximum throughput of up to 84.2ML per day.

Challenge

To meet the maximum design station outflow of 93.6 ML/d the pumps and motors at all three water pump stations required upgrade with all discharge and reflux valves and actuators past their useful life also requiring replacement.

To achieve this, the new valve trains needed to be interfaced with new pipework into existing infrastructure requiring a temporary shutdown of each pump station.

Solution

Both technically and logistically complex, Water Engineering Technologies completed this upgrade within time and budget. The team:

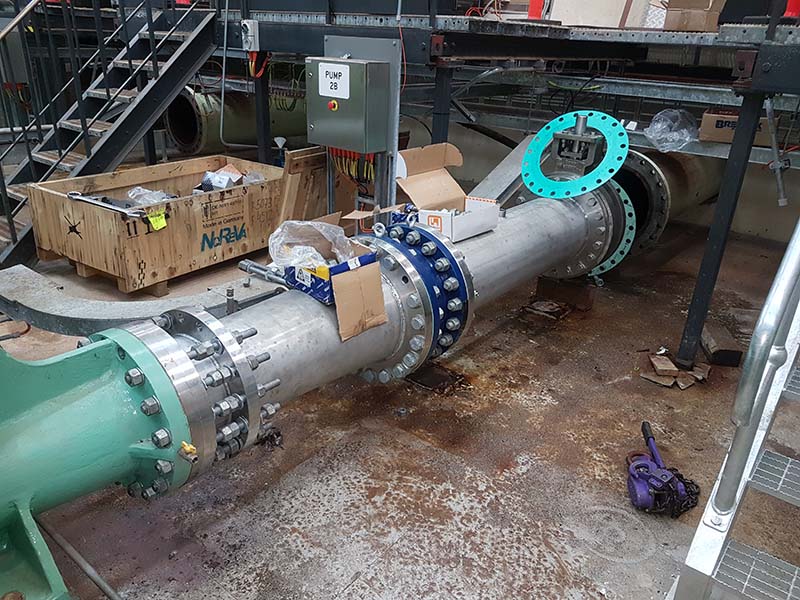

- Replaced the pump discharge gate valves and reflux valves

- Manufactured and Installed new pipe adapter spools between the new isolating valve and the dismantling joint

- Manufactured and installed new reflux valve safety cages

- Installed new wiring and SCADA links for the new actuators.

Water Engineering Technologies South Para workshop mechanical team took lead the design and physical installation of the new valve trains. The new pipework was specially tapered and constructed from stainless steel. In a display of skill and innovation, the fabrication team rolled then fabricated the tapered sections entirely in house delivering significant savings to the project.

To eliminate any customer supply interruptions, or introduction of water quality issues to the network, the team ensured the pipeline intermissions did not exceed 48 hours at a time. The team worked around the clock in 12 hour shifts so that pumping was brought reactivated as soon as possible. This was achieved by supplementing crews with tradespeople from Water Engineering Technologies Berri and Port Lincoln workshops.

With excellent planning and commitment to minimise customer interruption, the upgrade works were completed without incident and full pumping capabilities were brought back online within 18 hours – well short of the planned 48 hours. The pump stations now have new valve sets enabling high level pumping availability and reliability for years to come.

Pump unit 2A showing the newly-installed valve train on pump 2B ready

for tensioning of bolts and installation of new valve actuator.