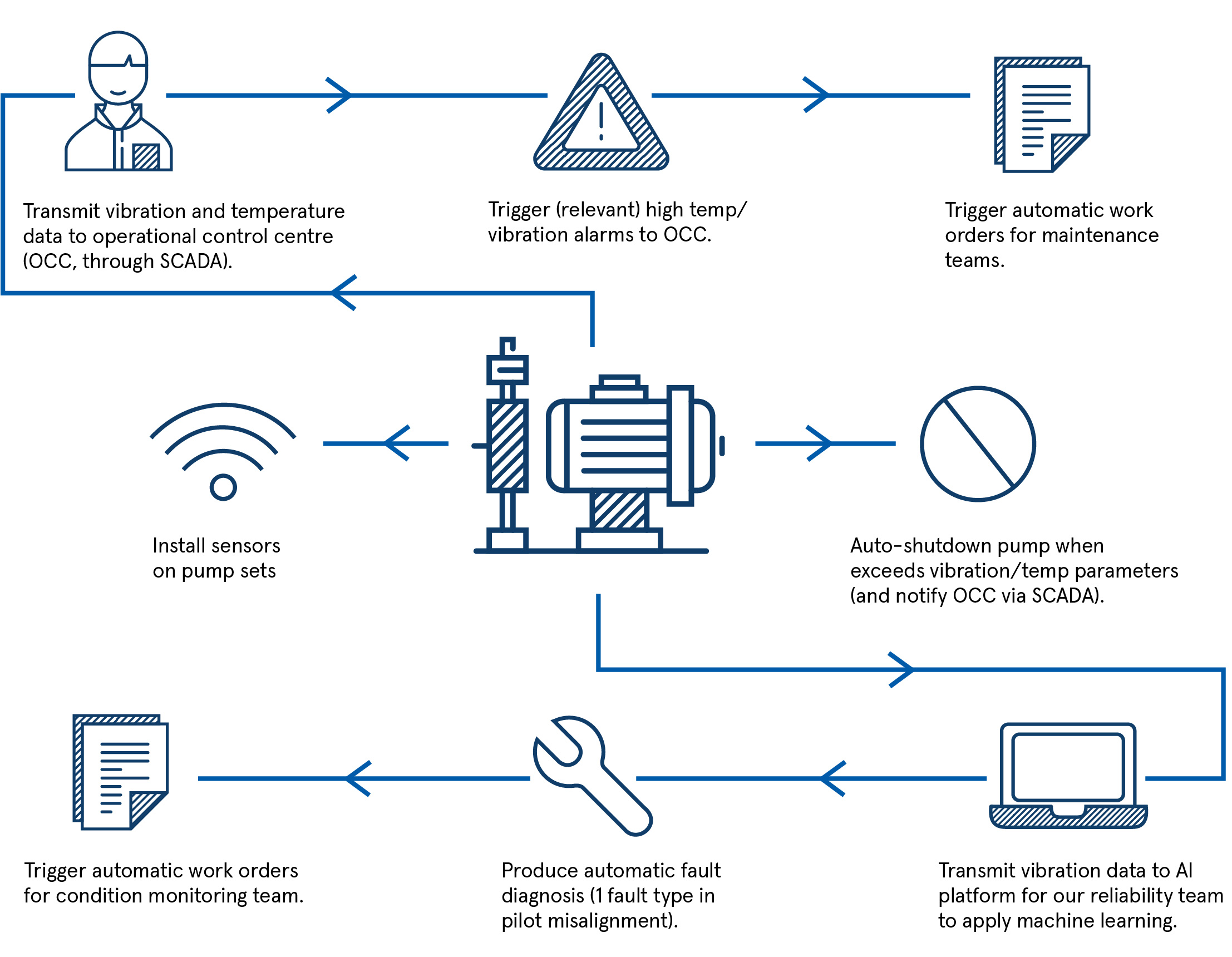

We use portable and on-line sensors to collect real time asset condition data that is combined with existing data, such as fault history, and reliability engineering techniques, data analytics and proprietary machine learning artificial intelligence (AI) algorithms to predict the repair or replacement needs of key assets, and avoid maintaining unnecessary redundancy.

By applying our smart technologies to critical rotating assets and analysing vibration, temperature, and displacement sensor data, we enable owners and operators of pump stations and other rotating assets to avoid ‘catastrophic’ failures, reduce repetitive preventative maintenance work and optimise maintenance investments.

Features of diagnostic and prognostic maintenance program include:

- use of joint reliability analysis, data analytics and cognitive (AI) algorithms

- fault diagnosis of rotating equipment that includes misalignment, looseness, imbalance and bearing wear

- automated creation of corrective work orders using AI algorithms that describe the predicted fault type and severity and recommended maintenance actions and timeframe

- generation of prescriptive maintenance reports

- an operational surveillance and alarm system

- a dashboard depiction of assets’ health and condition.

Our process for delivering these outcomes is described below.

Our performance and condition-based maintenance program enables owners of rotational assets, such as pumps, to maximise asset lifecycles and reduce operational costs, through the application of data-driven innovative reliability techniques.

Our performance and condition-based maintenance program enables owners of rotational assets, such as pumps, to maximise asset lifecycles and reduce operational costs, through the application of data-driven innovative reliability techniques.